The world of precision tools has witnessed a groundbreaking innovation with the introduction of anti-slip quantum dot-coated tweezers. These cutting-edge instruments are revolutionizing industries that demand meticulous handling, from electronics manufacturing to biomedical research. By combining advanced nanotechnology with ergonomic design, these tweezers address longstanding challenges in delicate material manipulation.

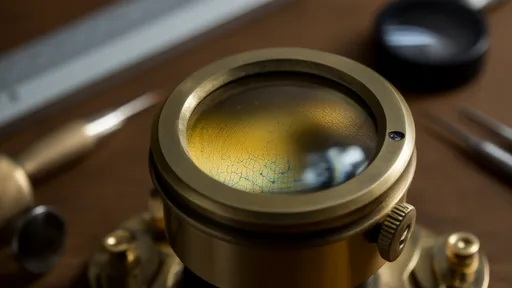

At the heart of this technological leap lies the quantum dot coating - a nanoscale marvel that fundamentally alters the surface properties of traditional tweezers. Unlike conventional coatings, the quantum dot matrix creates a tunable surface topography that adapts to different materials. When pressure is applied during gripping, the quantum dots undergo subtle structural changes that enhance friction precisely where needed. This dynamic response occurs without compromising the tweezer's inherent precision, offering users unprecedented control.

The development of these specialized tweezers emerged from years of interdisciplinary research, combining materials science with practical tool engineering. Scientists discovered that traditional tweezer surfaces often failed when handling ultra-smooth or moisture-sensitive components. The quantum dot solution not only solves these issues but introduces new capabilities. The coating's unique properties allow it to maintain optimal grip in various environmental conditions, including high humidity or extreme temperatures where conventional tools might slip.

Manufacturers have implemented the quantum dot coating through an innovative deposition process that bonds the nanoparticles at a molecular level. This creates a durable surface that withstands repeated sterilization cycles - a critical feature for medical and laboratory applications. The coating's thickness is precisely controlled to maintain the tweezers' fine tips while providing just enough texture for secure gripping. Early adopters report significant reductions in dropped components and improved handling efficiency, particularly when working with microscopic elements.

Beyond their functional advantages, these tweezers represent a shift in how we approach tool design. The quantum dot coating is just the beginning - researchers are already exploring ways to incorporate additional smart features. Some prototypes include embedded sensors that provide tactile feedback or change color when excessive pressure is applied. This evolution points toward a future where hand tools become interactive partners in precision work rather than simple implements.

The medical field has shown particular enthusiasm for this technology. Surgical teams appreciate how the anti-slip properties remain effective even when exposed to bodily fluids during procedures. Microsurgeons report improved handling of sutures and implants, with one vascular specialist describing a 40% reduction in slippage incidents during delicate procedures. The tweezers' compatibility with standard sterilization methods makes them practical for operating room use without additional maintenance requirements.

In electronics manufacturing, where component miniaturization continues to accelerate, these tweezers are solving previously intractable problems. Assembly technicians working with next-generation chips find they can manipulate components without the static issues that plague conventional metal tools. The coating's non-conductive properties prevent electrical interference while its grip ensures secure handling of the tiniest circuit elements. Several major electronics producers have begun transitioning their cleanroom tools to quantum dot-coated versions.

The environmental impact of this innovation deserves attention. Unlike some specialized tools that require frequent replacement, these tweezers demonstrate exceptional longevity. Their durable coating resists wear that would render conventional tools ineffective, reducing waste from disposable instruments. Furthermore, the manufacturing process for the quantum dot coating has been optimized to minimize hazardous byproducts, aligning with green chemistry principles. This combination of durability and sustainable production makes them an environmentally responsible choice for industries under pressure to reduce their ecological footprint.

As adoption grows, users are discovering unexpected benefits. Jewelers find the tweezers perfect for handling precious stones without marring their surfaces. Watchmakers appreciate the precise grip when positioning tiny mechanisms. Even hobbyists in fields like model building report superior performance compared to traditional tools. This broad applicability suggests the technology may become standard across multiple precision-requiring disciplines.

Looking ahead, researchers are exploring ways to enhance the quantum dot coating's capabilities. Early-stage developments include photosensitive versions that adjust their grip strength in response to light intensity - potentially useful for applications involving light-sensitive materials. Another promising avenue involves incorporating antibacterial properties directly into the coating matrix, which could prove invaluable for medical applications. As these enhancements mature, they may further cement quantum dot-coated tools as indispensable instruments in precision work.

The commercial availability of these tweezers marks a significant milestone in tool evolution. While currently positioned as premium instruments, manufacturing scale-up is expected to make them more accessible across price points. Industry analysts predict rapid adoption as word spreads about their performance advantages. For professionals who rely on precision tools daily, these quantum dot-coated tweezers aren't just an incremental improvement - they represent a fundamental shift in what's possible in delicate material handling.

Training and familiarization have emerged as minor challenges during initial deployment. Some users accustomed to traditional tweezers need brief adjustment periods to trust the enhanced grip completely. Manufacturers have responded with instructional materials highlighting proper techniques to maximize the tools' potential. Once users overcome this initial learning curve, satisfaction levels reportedly soar, with many declaring they would never return to conventional tweezers.

The success of quantum dot-coated tweezers is inspiring similar innovations across the tool industry. Research teams are investigating applications for other precision instruments where controlled grip is essential. Scalpels, probes, and micro-manipulators may soon benefit from similar nanotechnology enhancements. This ripple effect could transform entire categories of professional tools, ushering in a new era of performance and reliability.

As with any emerging technology, questions remain about long-term performance under continuous use. Accelerated aging tests suggest the coating maintains effectiveness through thousands of cycles, but real-world data will ultimately validate these findings. Early indications from pilot programs are overwhelmingly positive, with tools maintaining their anti-slip properties well beyond typical replacement cycles for conventional instruments.

The story of these tweezers serves as a compelling case study in applied nanotechnology. It demonstrates how fundamental scientific discoveries can translate into practical tools that solve real-world problems. By bridging the gap between laboratory research and industrial application, quantum dot coatings have proven their worth beyond theoretical promise. As manufacturing processes refine and applications multiply, this technology may well become the new standard for precision handling tools across countless industries.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025